The Dangers Of Skipping Regular Test & Tag

In today’s busy workplaces, electrical safety is often overlooked — until something goes wrong. Whether you're operating a café, managing a construction site, or running a corporate office, every environment relies on electrical equipment that must be safe, reliable, and compliant. But how often do tests and tags need to be done to ensure safety? The answer depends on the risks of your specific work setting and the type of equipment used. One thing is certain: skipping regular test and tag puts your staff, property, and business continuity at serious risk.

Let’s explore why test and tag are far more than a compliance box-tick and what can go wrong when they are ignored.

Electrical Hazards From Untested Equipment

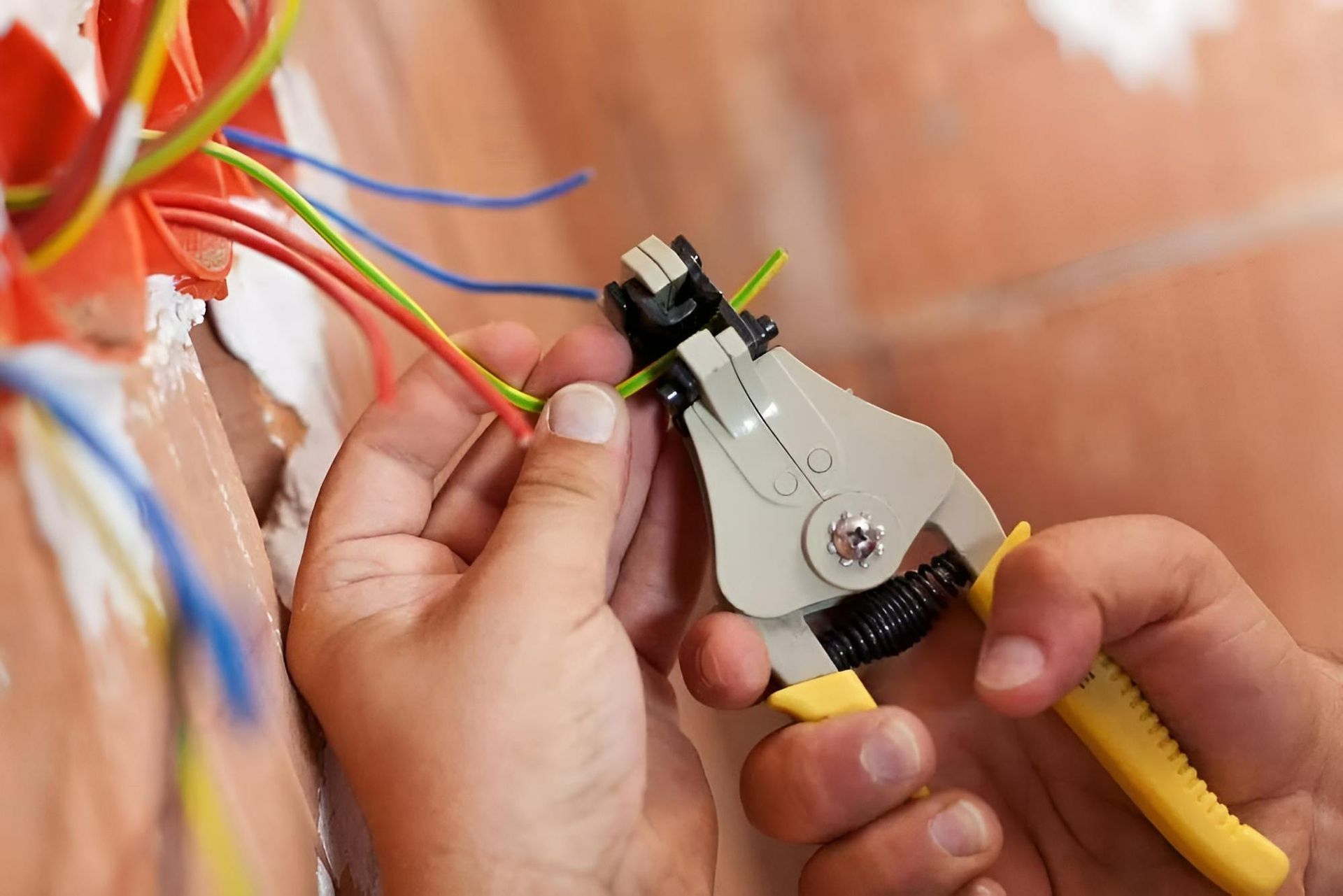

Every year, electrical incidents in Australian workplaces result in serious injuries, equipment damage and even fatalities. Often, these events are caused by unnoticed wear and tear — frayed cords, damaged plugs or overheating components. These issues can remain hidden without regular inspection and testing until an incident occurs.

A licensed electrician performing test and tag services can detect invisible faults to the untrained eye. This includes insulation breakdown, earth continuity issues, and polarity problems. When testing is skipped, here’s what can go wrong:

- Overloaded or overheating equipment sparking electrical fires

- Damaged cords leading to electric shock

- Faulty appliances causing power outages

- Risk of burns or electrocution from exposed wiring

- Unnoticed grounding issues resulting in equipment malfunction

Employer Responsibility for Electrical Safety

Beyond moral duty, business owners and managers are legally responsible for ensuring the safety of electrical equipment. Workplace Health and Safety (WHS) laws in Australia mandate that employers provide a safe work environment, including identifying and managing electrical risks.

Key legal points include:

- WHS Regulations: Employers must eliminate or minimise electrical risks as far as reasonably practicable.

- AS/NZS 3760 Compliance: This standard outlines inspection and testing intervals, methods, and tag requirements.

- Duty of Care: Failure to comply with these obligations can lead to prosecution, fines, or compensation claims.

Risk of Denied Insurance Claims

Insurance provides financial protection — but that protection often comes with terms. In the case of electrical-related incidents, insurers may reject a claim if it’s found that equipment hadn’t been tested or maintained as per legal or policy obligations.

Businesses that skip regular test and tag procedures expose themselves to claim disputes. Even if the damage wasn’t directly caused by negligence, the absence of maintenance records can lead to issues.

Here’s what could happen:

- Insurance providers requesting test and tag logs during claims

- Claims rejected due to non-compliance with safety standards

- Delays in processing due to inadequate documentation

- Higher premiums following uncovered negligence

How Often Test & Tag Is Required

One of the most common questions business owners ask is how often tests and tags need to be done. The answer varies depending on your industry, the type of equipment in use, and the surrounding environment. Australian standards outline specific intervals to ensure compliance and reduce risk across different settings.

Here’s a general guide to common workplace types:

- Construction sites should test and tag all portable appliances every 3 months due to high-risk conditions and heavy use.

- Offices, where equipment is stationary and used in a low-risk setting, require testing of non-portable items approximately every 5 years.

- Factories & workshops with portable tools used frequently should undergo testing every 6 to 12 months.

- Hostile environments, such as those exposed to dust or moisture, demand more frequent testing — typically every 6 months for all equipment.

- Hospitality venues like kitchens and cafés should have portable kitchen appliances tested at least every 12 months.

Downtime From Avoidable Equipment Failure

When electrical faults are discovered during daily operations, they usually require urgent repairs or replacements. This not only affects productivity but can also bring parts of the business to a standstill.

Letting equipment fail without testing puts the business on the back foot.

Here's what downtime could look like:

- Operations halted due to a power supply interruption

- Delayed projects from broken power tools or unsafe appliances

- Reactive call-outs and emergency repairs

- Staff unable to use essential equipment safely

- Financial loss from delayed services or output

Dangers of Unqualified Equipment Checks

Some businesses rely on in-house staff for visual inspections or basic plug-in testing. While this might seem cost-effective, it leaves room for critical safety risks. Professional electricians use calibrated test equipment to measure insulation resistance, polarity, earth continuity and leakage — none of which can be properly assessed visually.

Common oversights by untrained staff:

- Missing internal faults not visible on the surface

- Incorrect tagging without full testing

- Overlooking earth leakage, which can cause electrocution

- Failing to isolate and tag faulty items properly

Only a trained electrician can complete the full process safely and accurately. Only licensed professionals can perform testing and tagging under relevant standards in many industries.

Protecting Staff Through Regular Maintenance

Creating a safe workplace involves more than floor markings and safety signage. Test and tag is a practical step toward reducing incidents that can injure staff and interrupt operations. Business owners who proactively approach equipment maintenance show their teams that safety is a real priority.

Imagine an employee receiving a mild electric shock from an old fan in the break room. Not only is this a health and safety breach, but it also damages morale and can lead to lost time and compensation claims. This kind of scenario is easily avoidable through a proper tagging schedule that removes unsafe equipment from circulation.

Importance of Test & Tag Records for Audits

Whether you're preparing for a compliance audit, tender application or insurance renewal, well-kept test and tag records make life easier. A qualified electrician will provide documentation after each inspection, including tags with test dates and retest due dates. This builds a clear paper trail that shows you’ve done your due diligence.

Recordkeeping benefits include:

- Up-to-date tagging with colour codes or barcodes

- Digital registers for quick compliance verification

- Evidence for WHS audits or inspections

- Reduced stress during insurance claim investigations

- Easy scheduling for future test cycles

Take Action with Our Trusted Electrician in Casino

At Peter Gow Electrical, we understand the importance of workplace safety and are committed to helping businesses meet their obligations with ease. Our licensed electricians provide comprehensive test and tag services tailored to your industry needs. We don’t just test — we document, schedule, and advise to keep your workplace safe, compliant, and protected.

Ready to reduce risk and safeguard your people and equipment? Give us a call or get in touch via our contact page today. We’ll help you monitor your compliance and ensure your business runs smoothly.